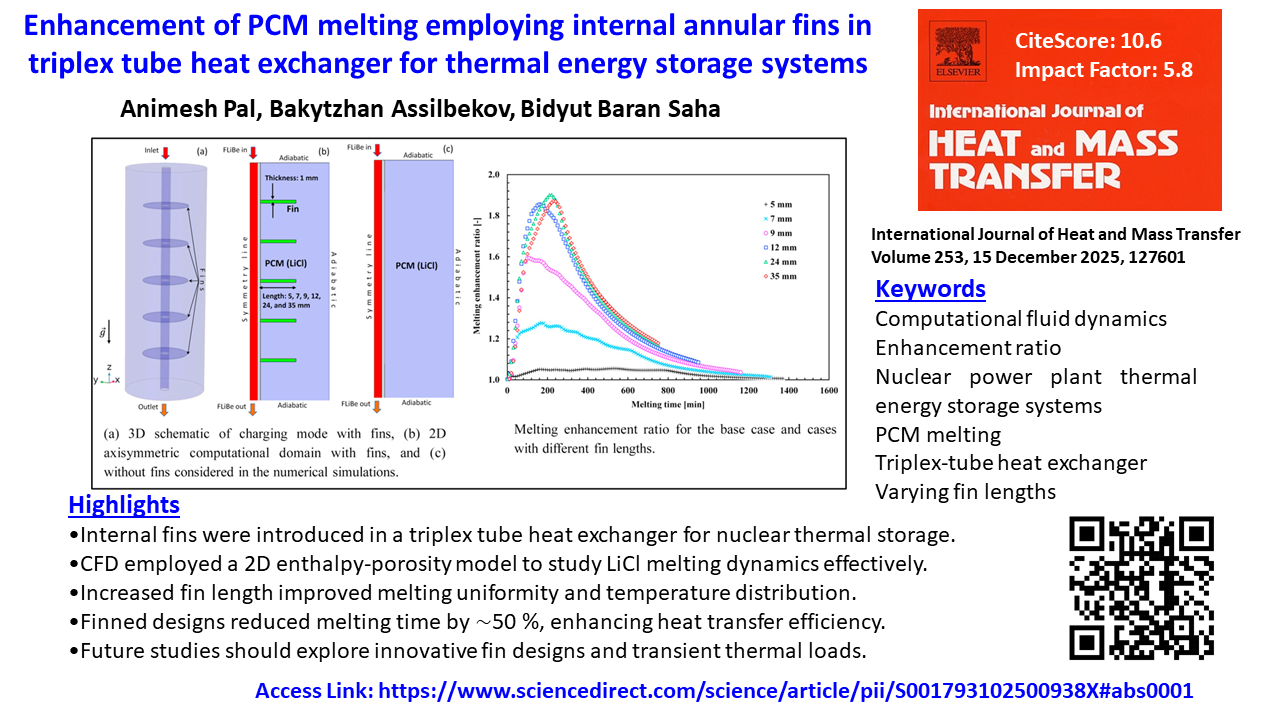

Recent publication of Dr. Animesh Pal: Enhancement of PCM melting employing internal annular fins in triplex tube heat exchanger for thermal energy storage systems

Abstract:

This numerical investigation, employing computational fluid dynamics, assesses the performance of triplex tube heat exchangers utilizing lithium chloride (LiCl) as a phase change material (PCM) for thermal energy storage in nuclear power plants. The study analyzes heat transfer characteristics during charging mode, comparing finned and unfinned configurations. Furthermore, the impacts of six different fin lengths (5, 7, 9, 12, 24, and 35 mm) on LiCl melting dynamics and overall system efficiency are examined. Various parameters, such as the melting process, temperature distribution, melting enhancement ratio, and heat flux, are analyzed to assess the effectiveness of each configuration. It is observed that the inclusion of fins demonstrably accelerates LiCl melting, increasing the contact area with the FLiBe heat transfer fluid; longer fins further amplify this effect. The melting time is reduced by approximately 50 % with 35 mm fins compared to the unfinned configuration, which is attributed to the enhanced heat transfer surface area and the generation of vortex motions that promote uniform temperature distribution within the PCM. Results also show that adding fins and increasing their length from 5 mm to 35 mm significantly decreases the surface-averaged heat flux value. The findings of this numerical investigation have practical implications, providing valuable insights into the design and optimization of nuclear power plant thermal energy storage systems and contributing to the advancement of sustainable and reliable energy generation technologies.

More details: https://www.sciencedirect.com/science/article/pii/S001793102500938X#abs0003